GOM Scan 1

– The next small thing –

GOM Scan 1 is here to open up new possibilities. Industrial standards such as GOM fringe projection technology and Blue Light Technology deliver the foundation for detailed and accurate 3D meshes. Meanwhile, the integrated software GOM Inspect helps you apply the mesh to any project you want: 3D printing, reverse engineering or part inspection. So, go ahead and start something big.

ACCURACY THROUGH INNOVATION

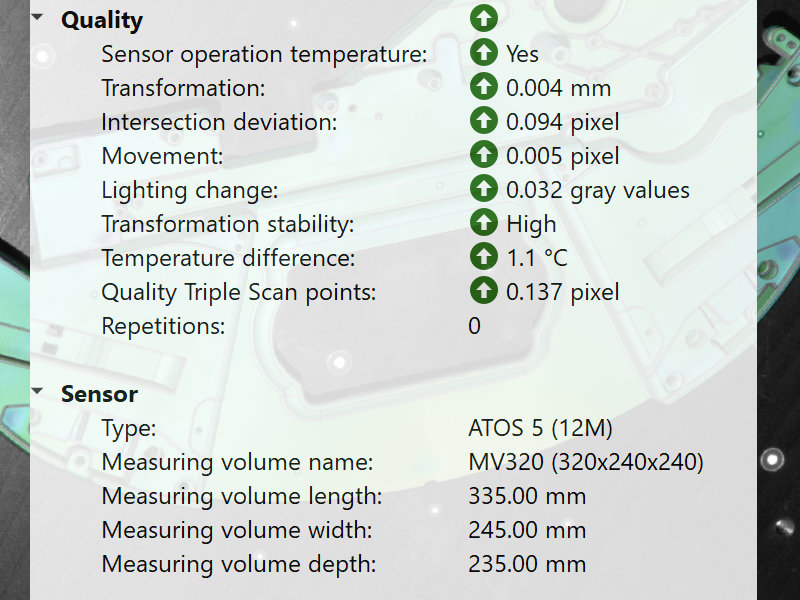

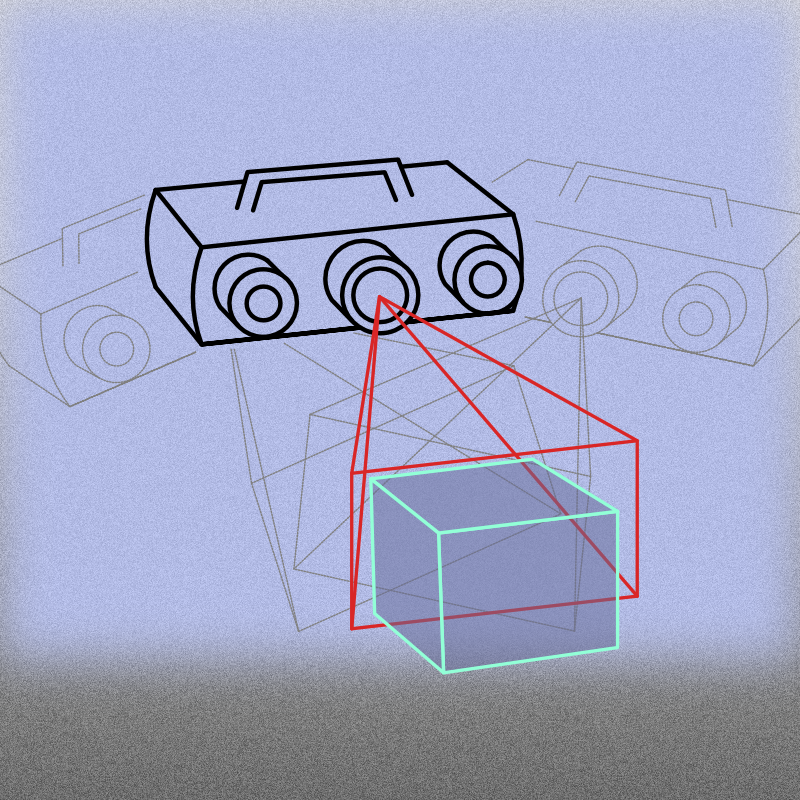

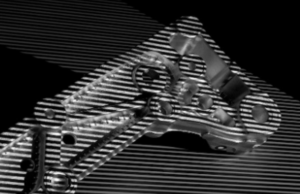

GOM Scan 1 is powerful, amazingly simple to use and really very accurate.GOM Scan 1 features a compact shape and robust design filled with advanced technologies. From GOM’s Blue Light Technology to the stereo camera principle, this sensor is built to deliver 3D data with high precision.

FUNCTIONAL FEATURES

Blue Light Technology

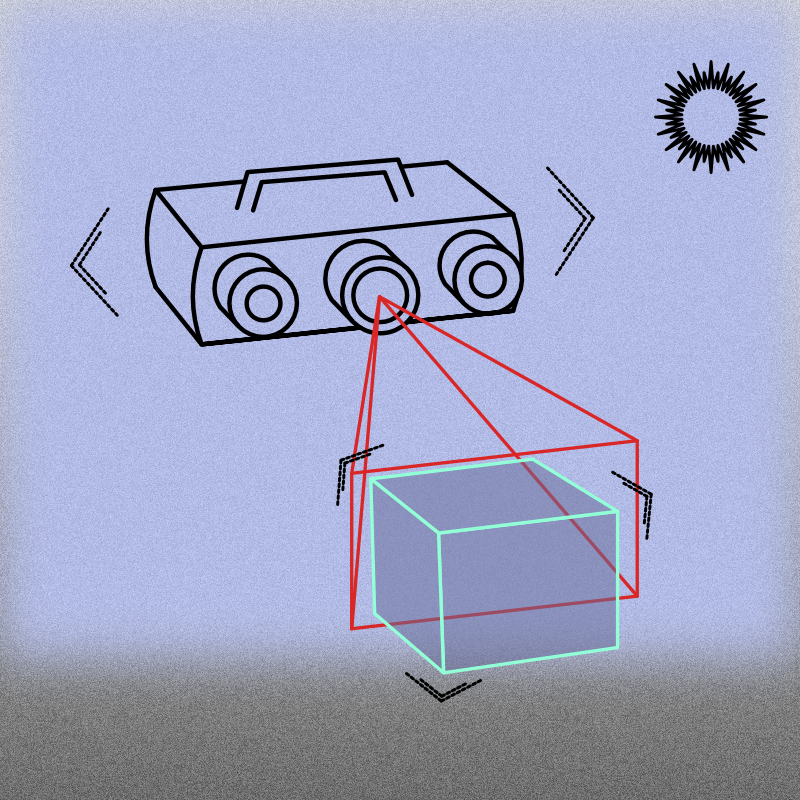

The projection unit of the new GOM Scan 1 is based on Blue Light Technology. Since the sensor works with narrowband blue light, interfering ambient light can be filtered during image acquisition. Due to its powerful light source, short measuring times can be achieved.

Technological Innovations

CAPTURE AND CREATE YOUR IDEAS

GOM Scan 1 with GOM Inspect is a system to support your entire workflow. It helps you to get accurate and comprehensive measurement results and makes part inspection effortless. Import and align CAD and mesh files, create surface comparisons, inspection sections and generate reports – easily and efficiently.

APPLICATIONS

GOM Scan 1 versions

GOM Scan 1 is the entry-level solution for professional 3D measurements. In both manual and semi-automatic configuration this is the ideal choice for capturing 3D data from small and medium parts.

Manual

With a weighing of only 2.5 kg and its compact design, the GOM Scan 1 is very light and can be moved with great ease. It can be used on a desk stand or a tripod in the metrology room or in the design office.

Semiautomatic

In combination with the GOM ROT 350 rotary table, GOM Scan 1 can be used to measure parts semi-automatically, simplifying the process and shortening the measurement time for each part.

GOM Scan system 1 – general configuration

Prepared in detail

ATOS sensors are not just simple 3D scanning equipment.

Because we have experience working in the field, we have put together a set of tools and accessories that we have included as standard in the package delivered so that the new owner of the equipment can successfully start work from day one. All items come organized in the carrying case so that they can be easily accessed when needed.

A set of consumables is included (reference markers, anti-glare spray, etc.)

Training and technical support

Training is essential and for this reason we offer the training of your staff through multiple training sessions, in Romanian, with GOM authorized instructors.

Benefit from 24/24 premium support for any software or hardware issues.

Scanning & Reverse Engineering Packages

Depending on the specifics of your applications, you can opt for one or more Design X licenses along with the appropriate sensor and measurement volumes. For any additional details or turnkey solutions please contact us directly or access the Request a Quote button. GOM Scan 1 sensors are part of this offer or you can choose one of the options below.